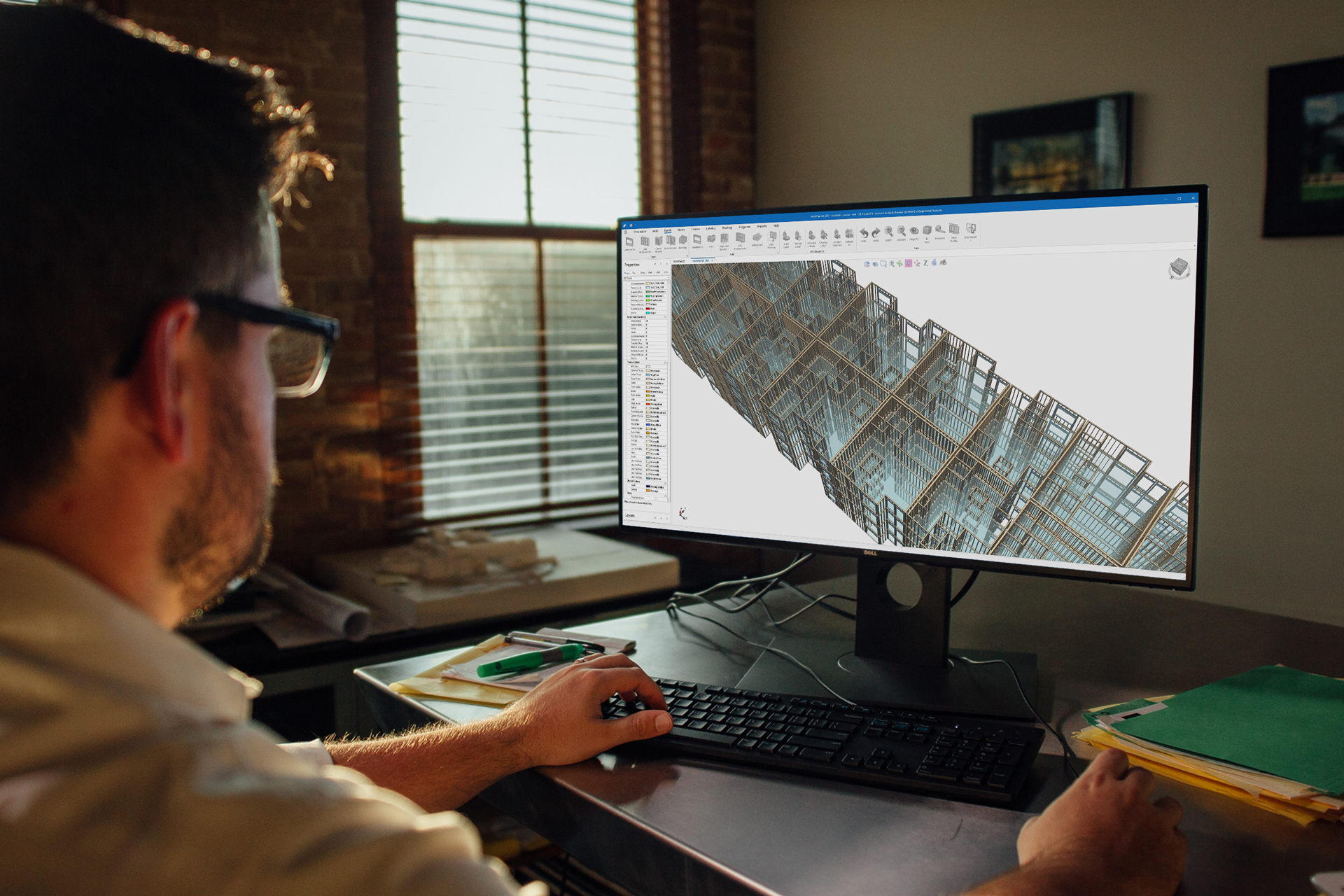

Does this sound familiar? A truss fabricator makes the decision to invest in their business to increase capacity. They buy the latest and greatest automated saw, automated jigging system, or even a projection system. The new machinery is guaranteed to increase throughput versus what they are using today. Two months into the new equipment, throughput is equal to or only slightly improved.

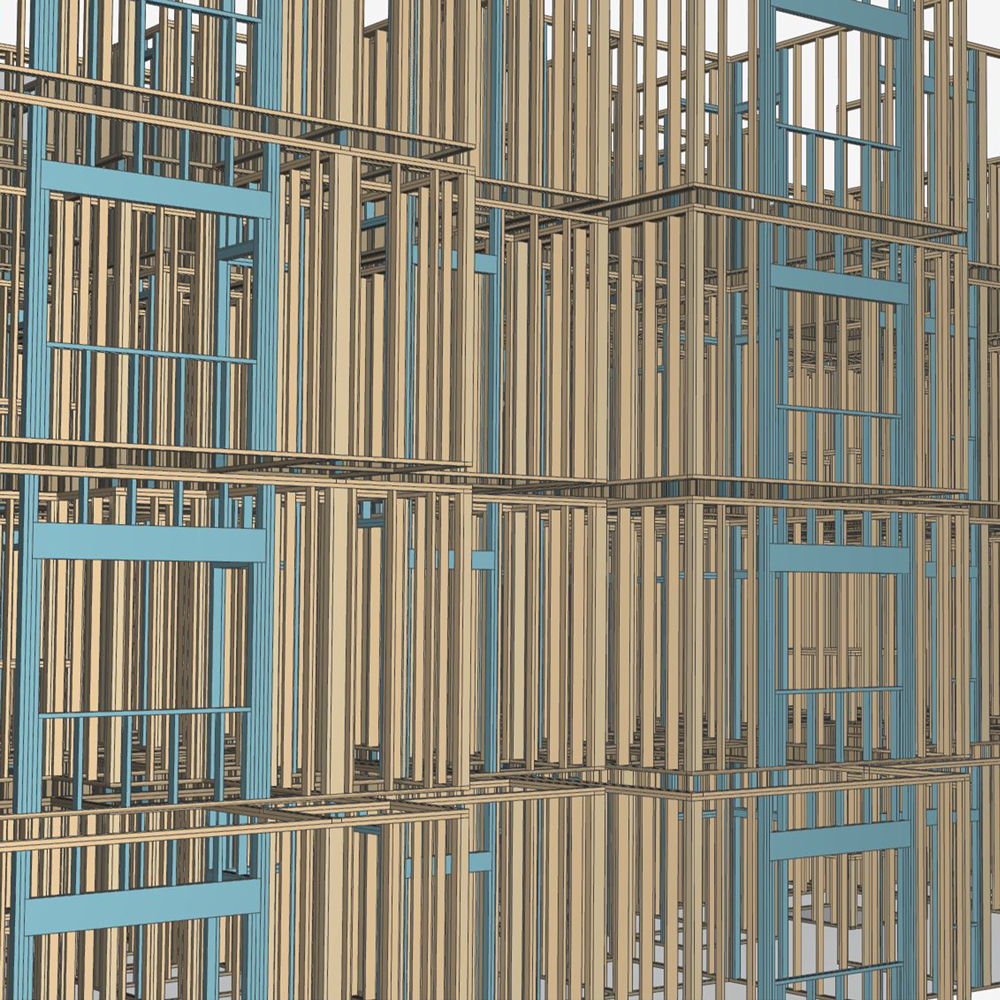

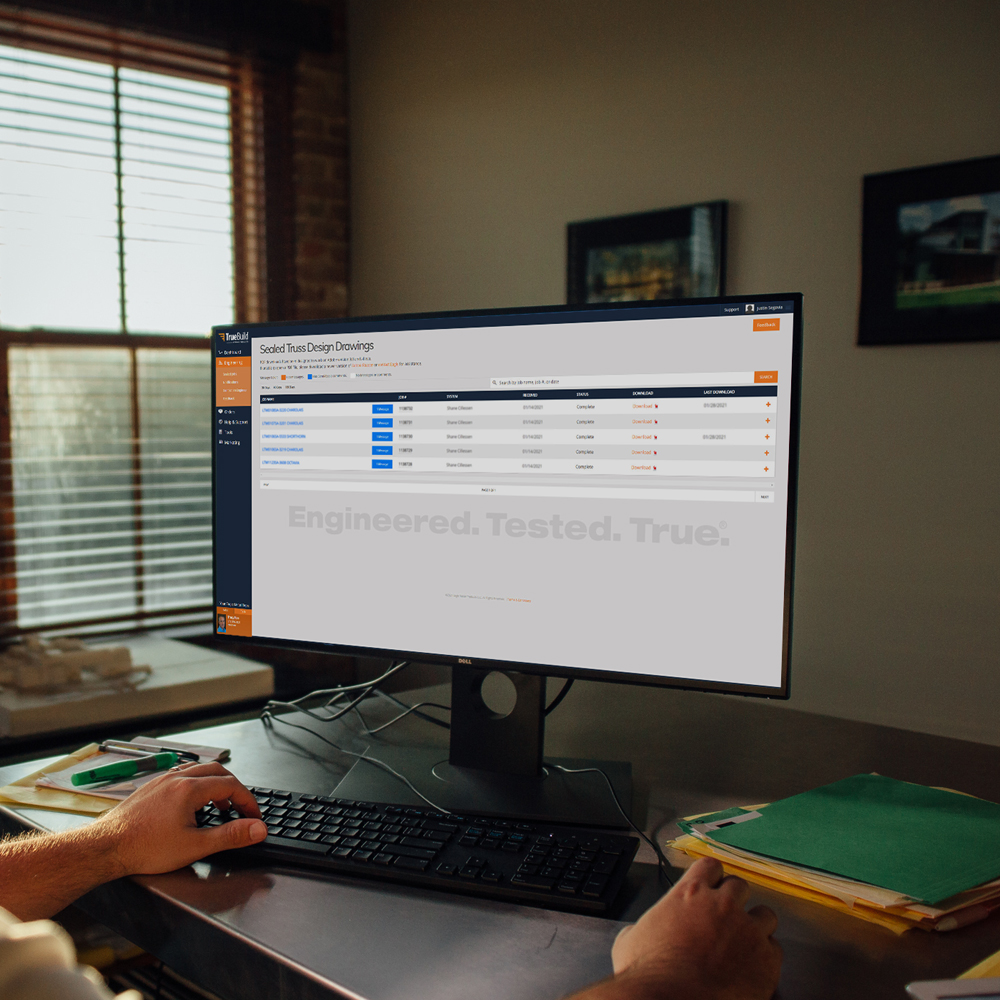

The bottom line is that any piece of new equipment requires an assessment and likely an adjustment to any production operation. Enabling you to make those decisions, TrueBuild® Batch gives you the flexibility and an easy-to-understand interface to adjust your cutting and assembly output to any equipment combination. From saws to tables to projections systems, TrueBuild® Batch can make your operations more efficient and leverage your equipment investments.

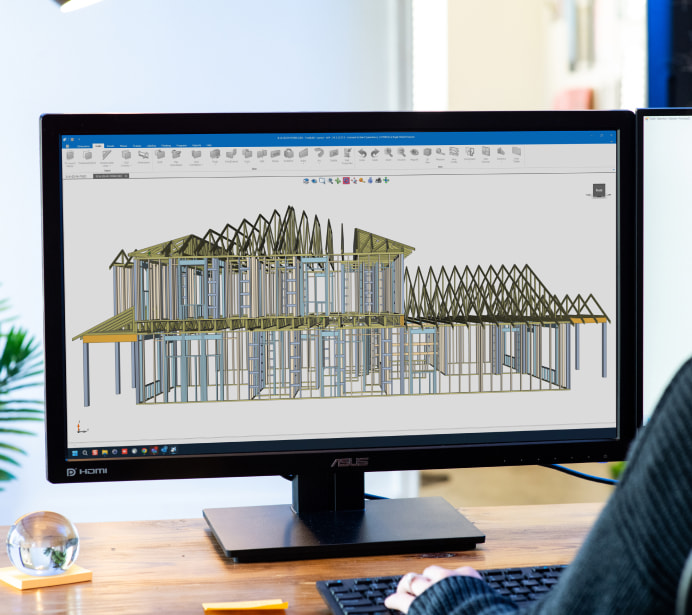

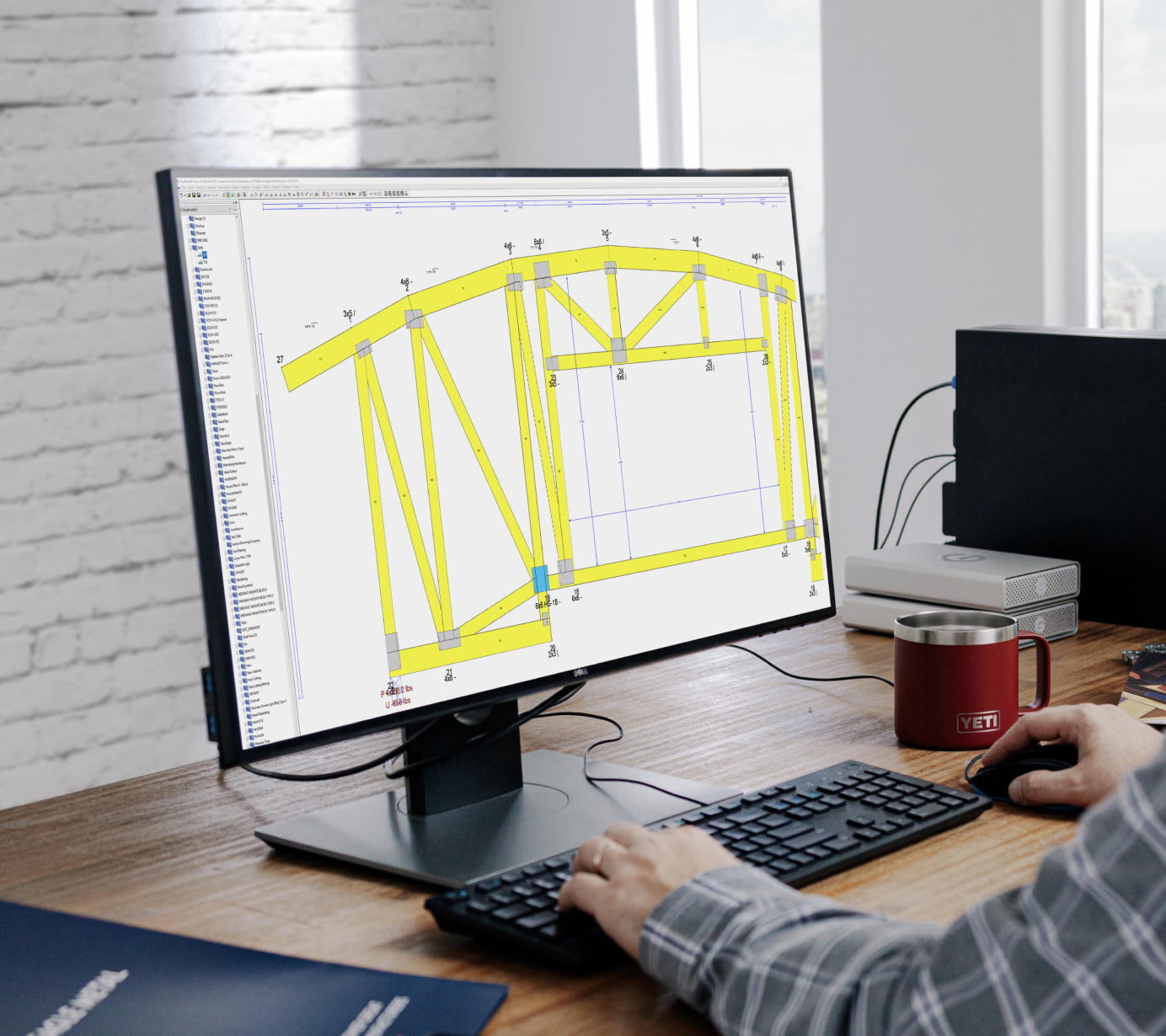

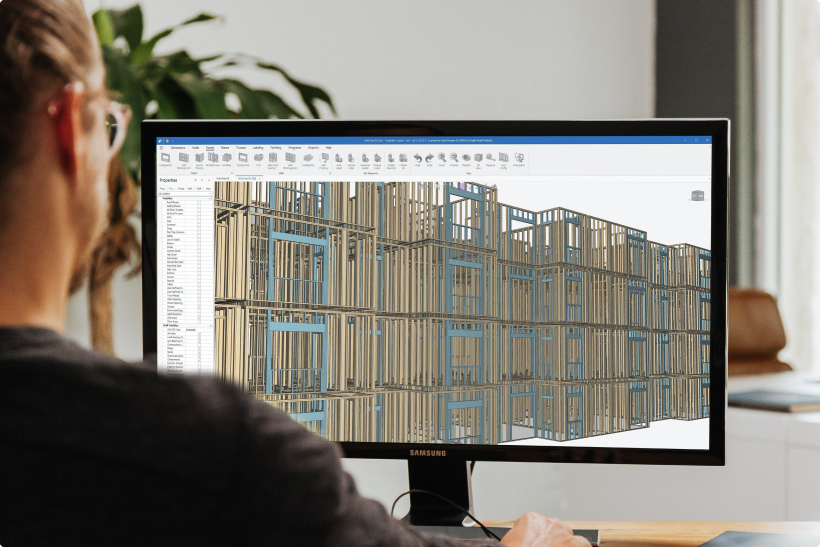

Drive your cutting and assembly operations precisely, with easy file output and controls to automated equipment. Here’s how it works:

- Assign specific board types based on plant parameters and send the right piece, to the right saw in the right sequence.

- Generate electronic production files for all computerized saws, jigging and projection systems.

- View production metrics for estimated cut, setup, and fabrication times to ensure precise scheduling.

- Use comprehensive production controls to define batch groups with customized pick lists, cutting tickets, stacking, and shipping reports.

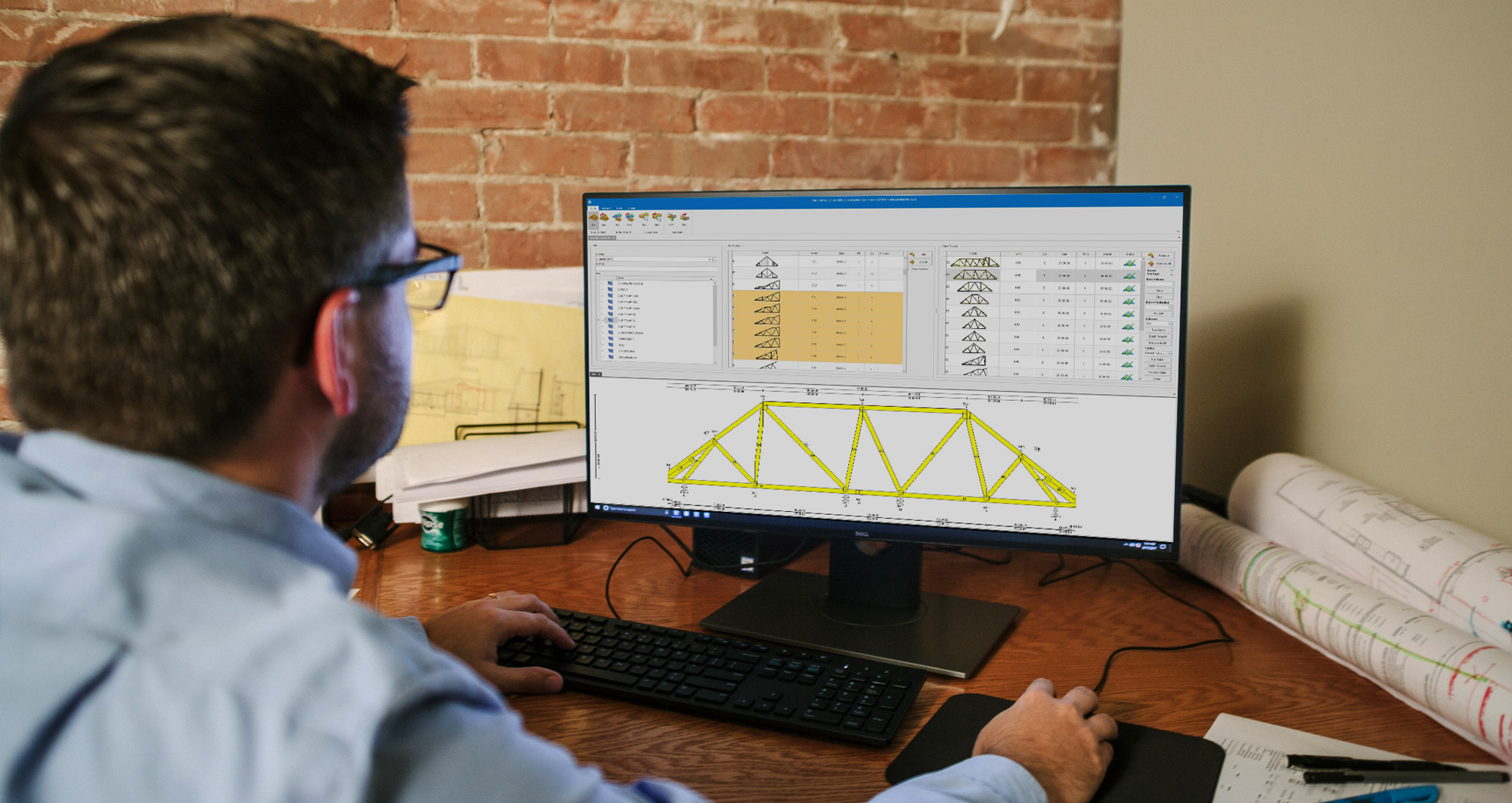

The Batch software system adds value to your operations by:

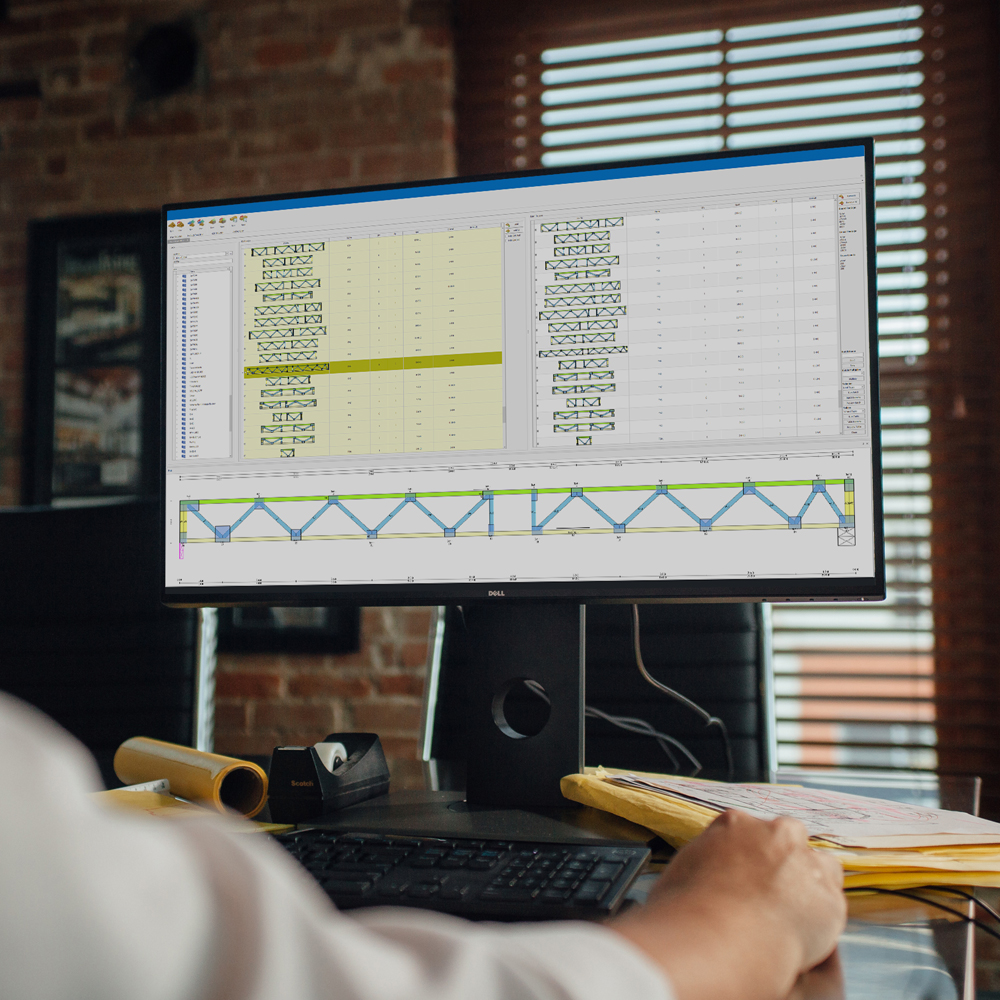

- Integrating with the automated equipment you already own.

- Reducing errors with color organization based on size, grade, cuts, or piece type.

- Allowing you to customize saw schemes to match your company’s needs.

TrueBuild® Batch is flexible enough to be as simple or as sophisticated as you need it to be. A powerful piece of software that bridges the gap between design and production, it is a great tool for truss fabricators to maximize the efficiency of automated equipment investments.

If you have any questions or want to learn more about this or any other piece of the TrueBuild® suite of software solutions, please contact me directly any time or visit www.eaglemetal.com.