FAQ

Have a Question?

Questions and Answers for all things building components, offsite-construction, and using manufactured trusses and wall panels in your construction projects.

Contact UsWall Panels

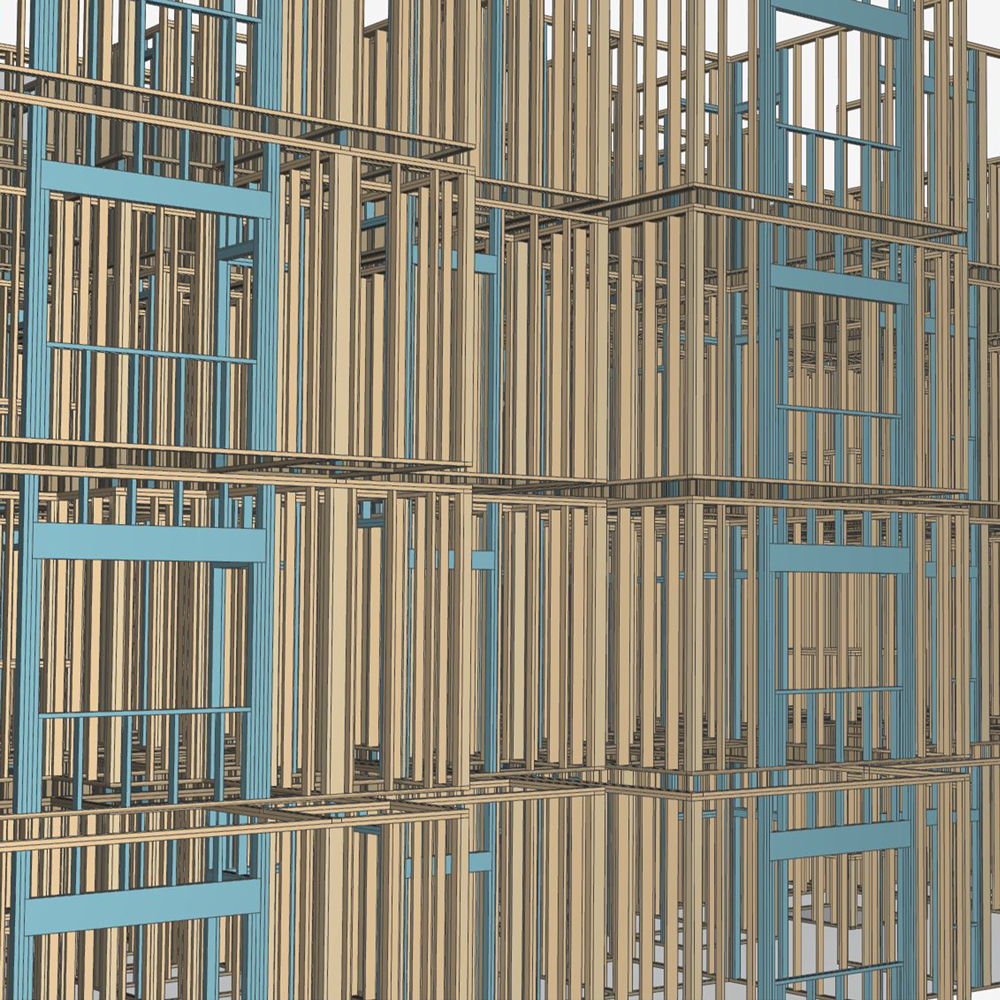

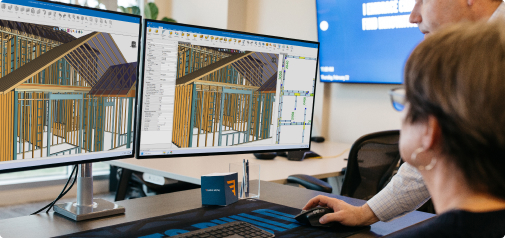

Wall panels reduce project complexity by minimizing variables and ensuring better consistency in material quality and construction tolerances.

Wall panels provide more accurate and consistent nail patterns for attaching studs to plates and sheathing to studs and plates compared to what is typically achieved in the field.

Wall panel manufacturers can apply sheathing in the factory, eliminating the need for on-site application and saving valuable time in the field.

Wall panel placement diagrams clearly identify each panel and its intended location, greatly simplifying the installation process and reducing any potential confusion.

The main advantage of using wall panels is the enhanced control over quality, consistency, and efficiency in framing projects, resulting in a more streamlined construction process.

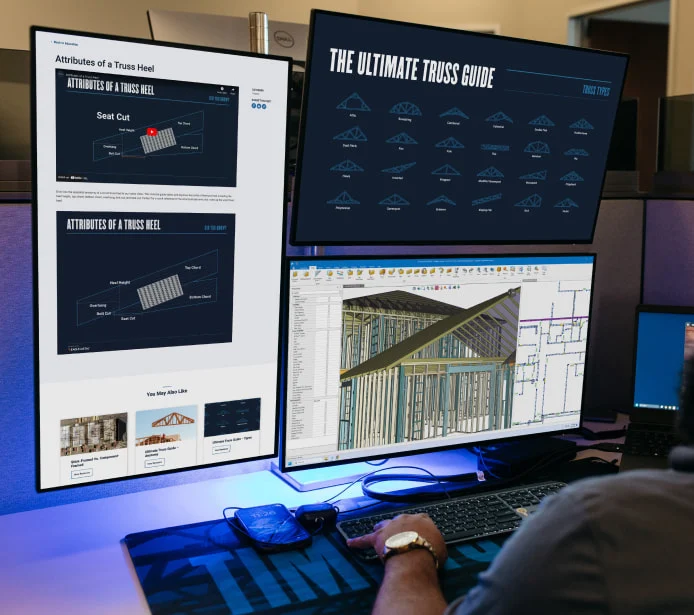

Roof Trusses

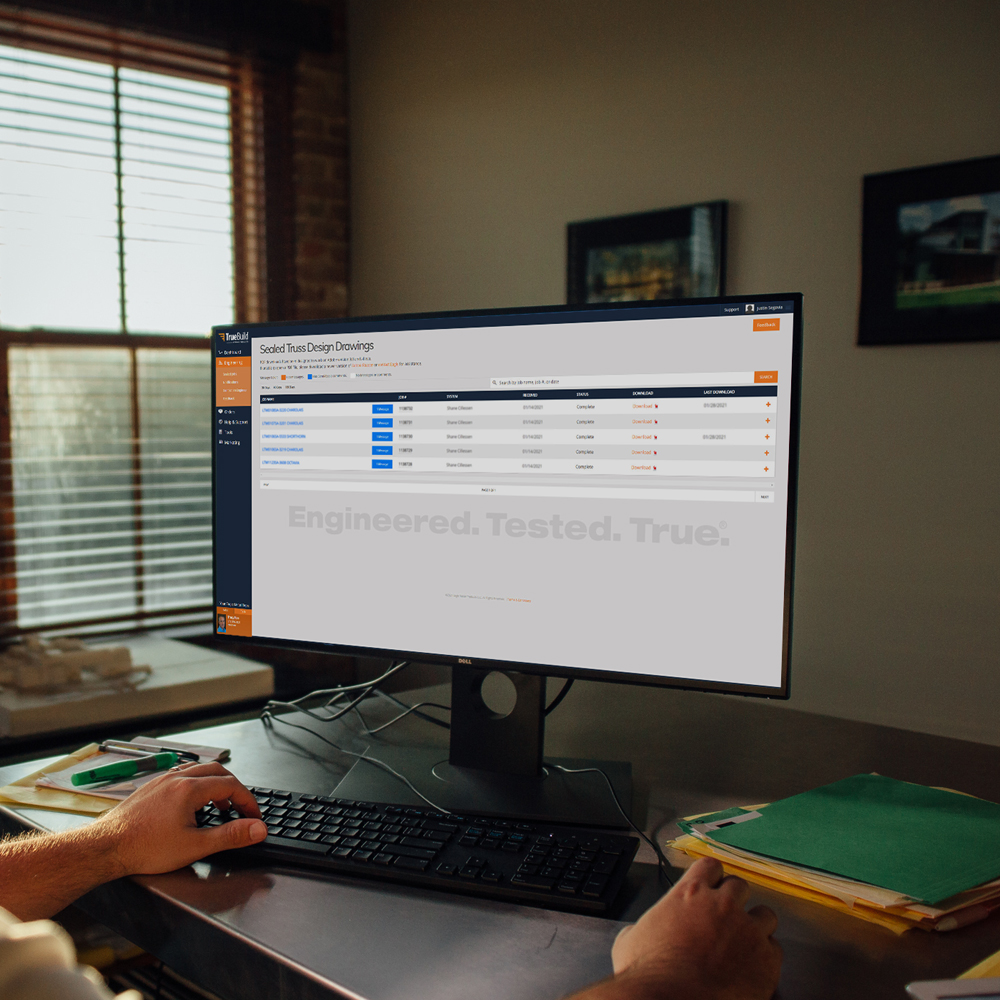

Offsite manufactured roof trusses offer several benefits, including faster construction timelines, increased precision in design and fabrication, reduced labor costs, and minimized material waste. They also ensure consistent quality and structural integrity, resulting in more reliable and long-lasting roof systems.

Offsite manufacturing for roof trusses promotes sustainable building practices by optimizing material usage, minimizing construction waste, and reducing transportation needs. The controlled factory environment allows for efficient resource management, leading to a smaller carbon footprint and less impact on the environment.

Floor Trusses

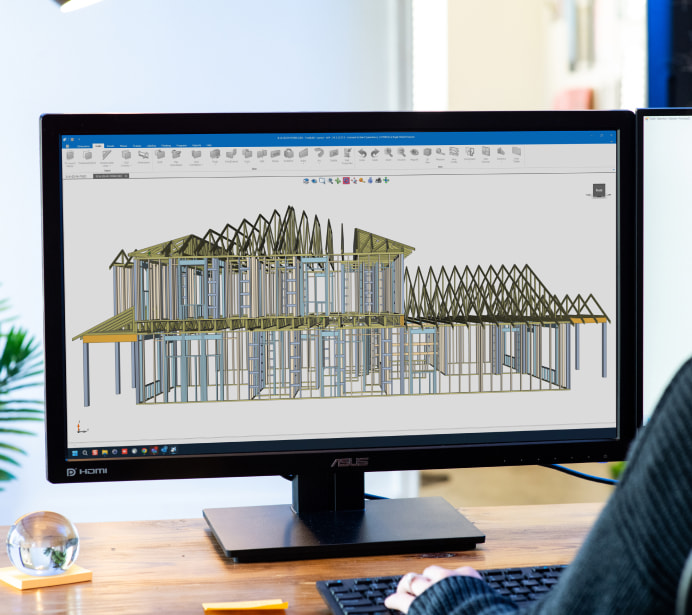

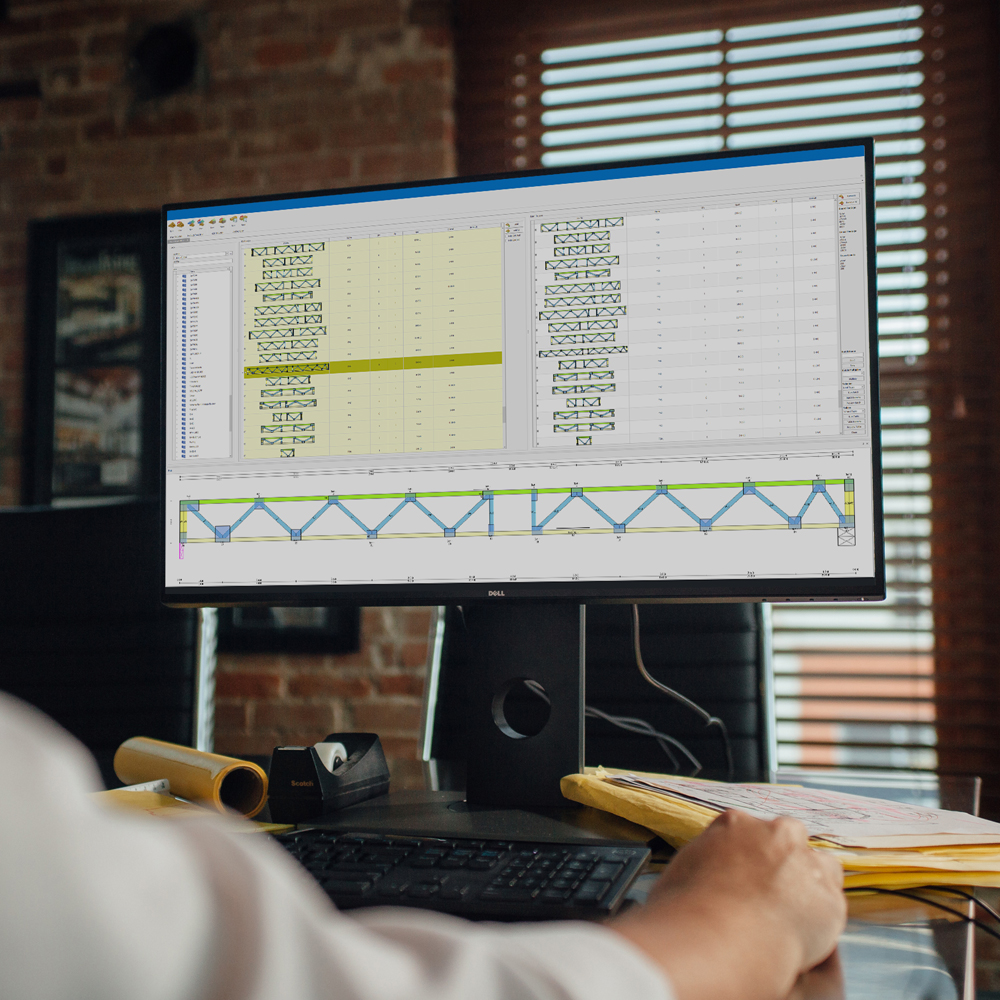

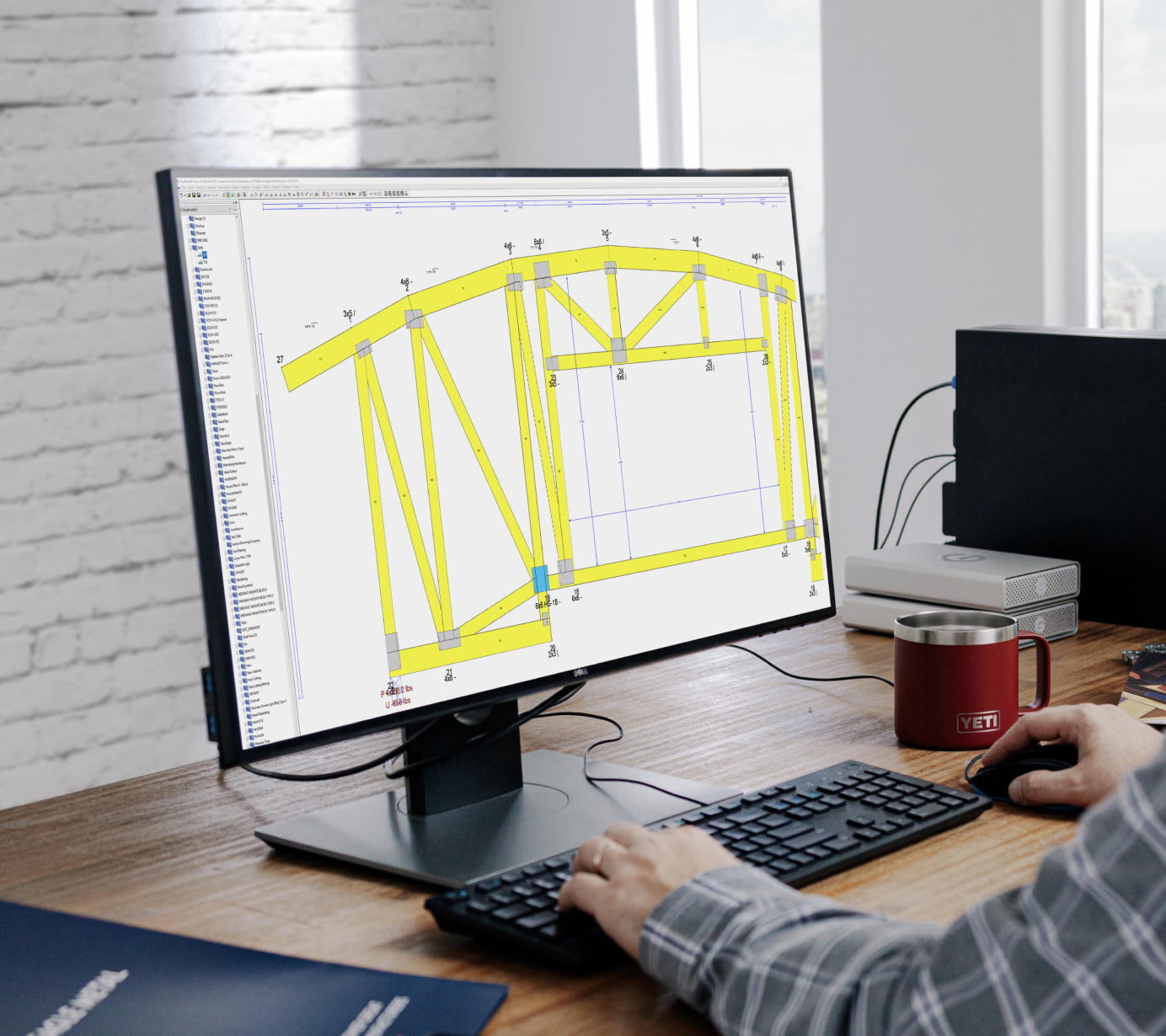

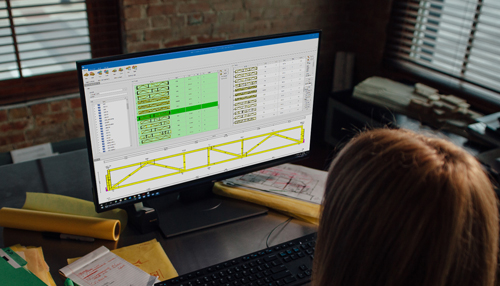

Offsite manufactured floor trusses provide design flexibility and customization options to meet various architectural and structural requirements. Truss manufacturers can utilize advanced 3D modeling software to create intricate designs tailored to specific building layouts, resulting in optimal load distribution and space utilization.

Offsite manufactured floor trusses arrive on-site as pre-engineered components, reducing the need for extensive on-site cutting and fabrication. This minimizes potential safety hazards and construction risks associated with traditional stick-built floor systems. Additionally, the precision engineering of offsite trusses ensures consistent quality and reduces the likelihood of structural issues during installation.

Join our newsletter for news and updates on our software

Submit