Continuing our articles series on better tools for wall panel design, it’s time to start talking about parametric 3D. So, what is parametric 3D and what does it mean for you?

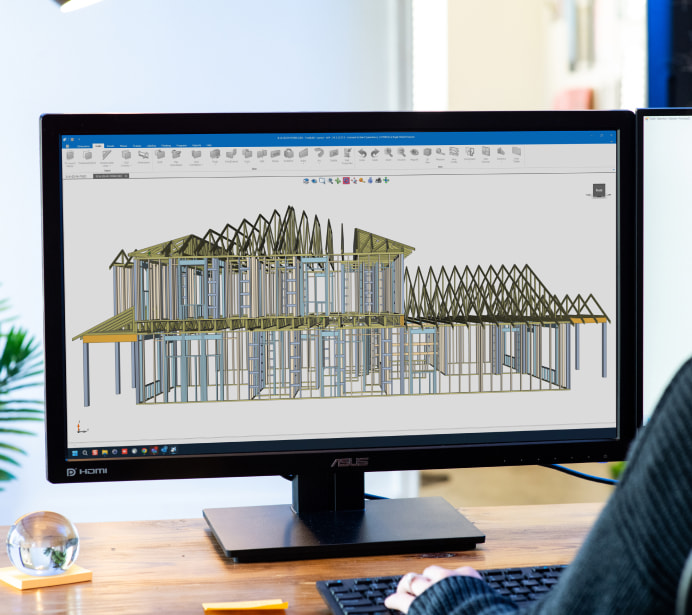

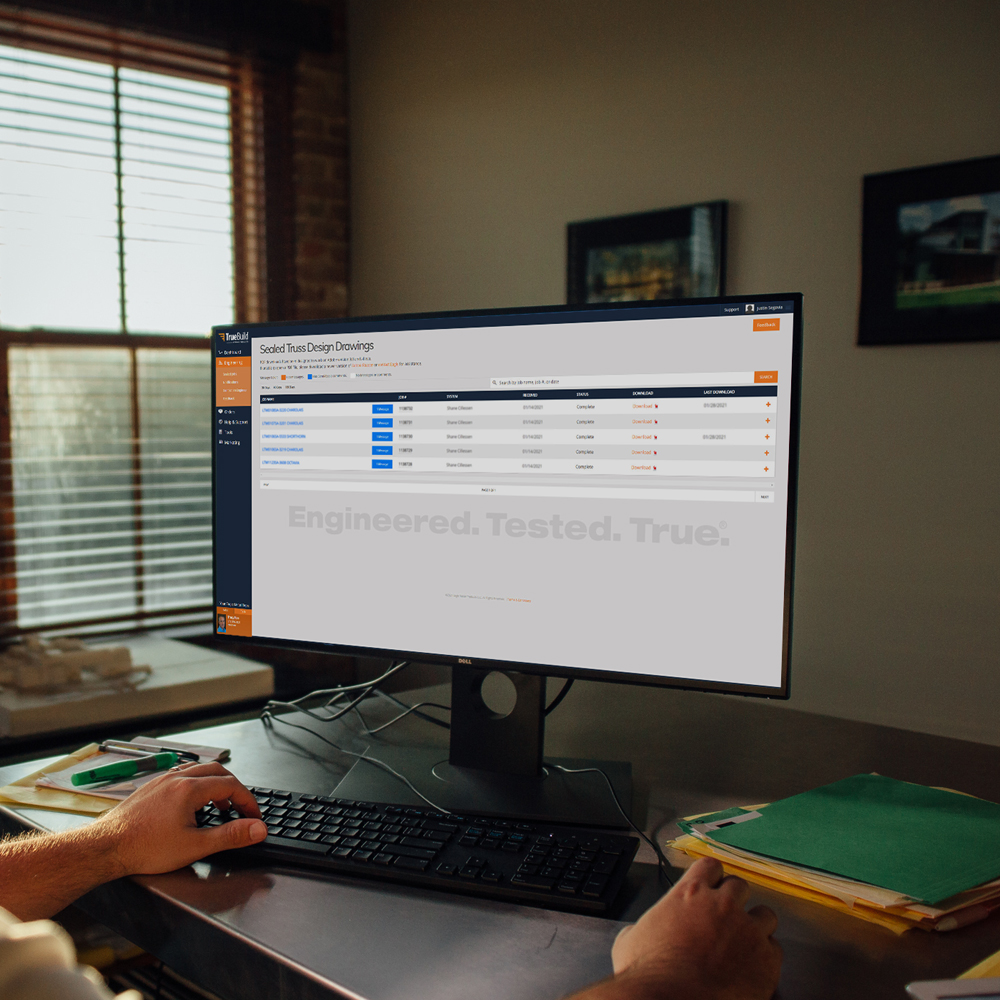

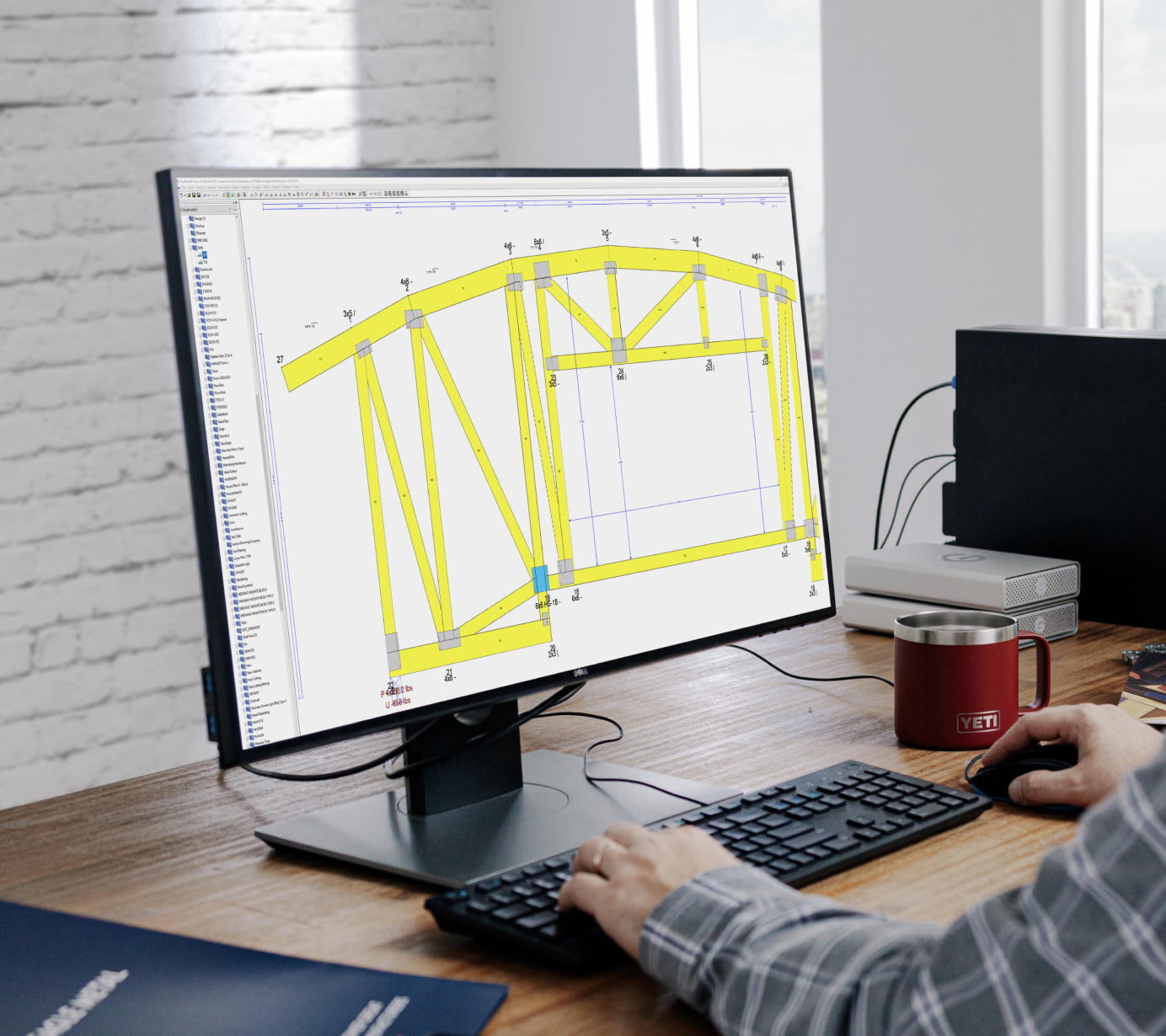

According to Wikipedia, “Parametric design is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response.” Moving past the jargon, what it means to you is – you can let the computer do more of the work! This definitely is true when you have our Truebuild® Layout working for you.

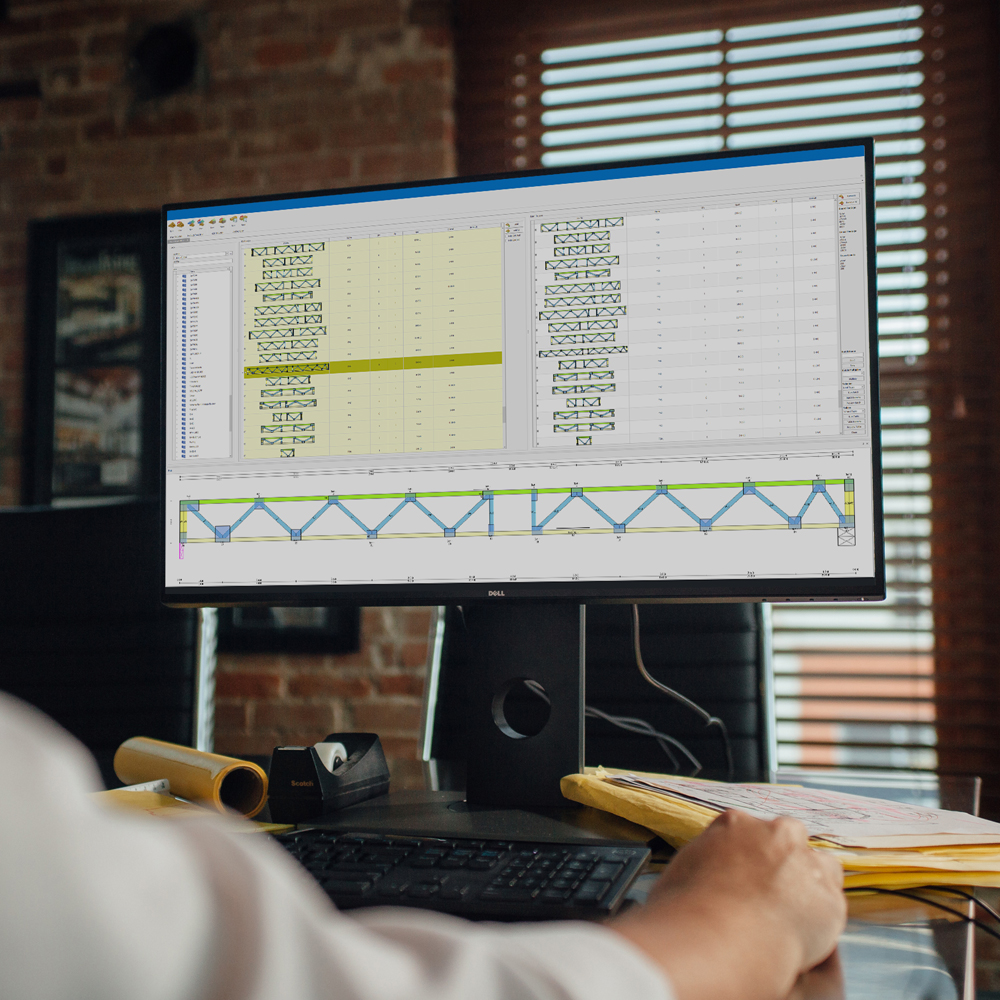

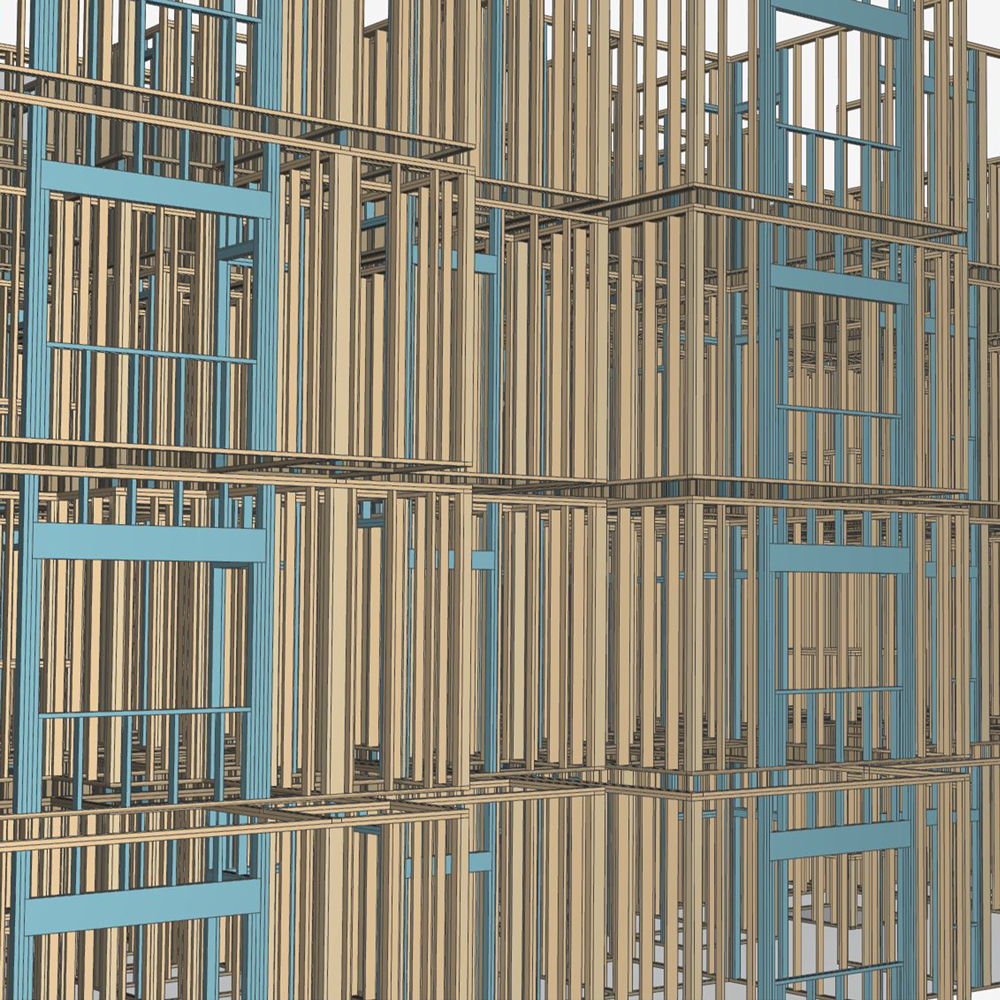

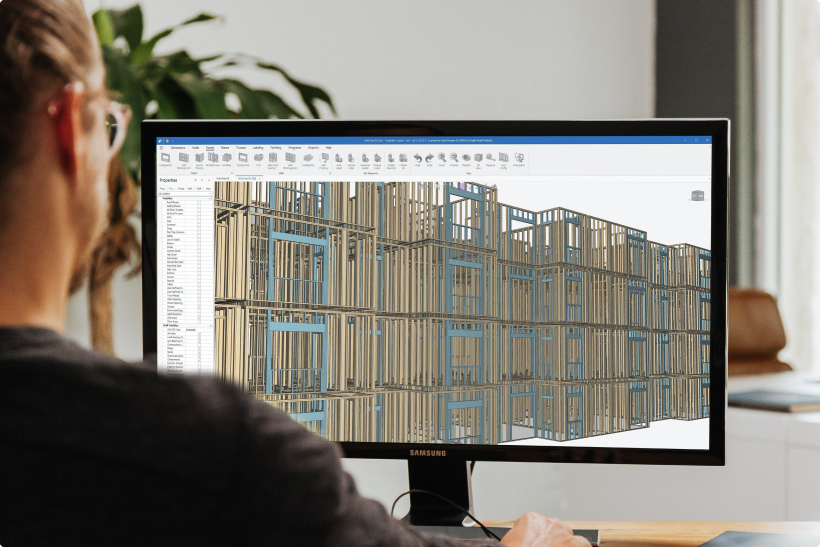

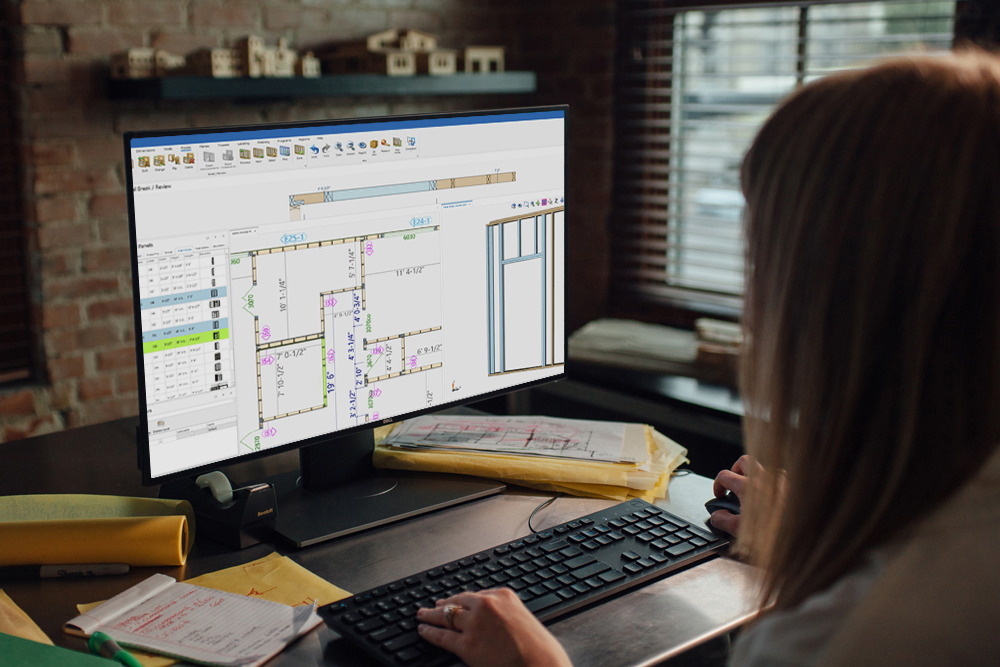

Wall panels are made up of different types of framing members. Examples of these members include plates, headers, jacks, sills, subcomponents, components, sheathing, etc. Truebuild® Layout with panel design provides technicians with the tools to create libraries for all these members and specified framing methods to be used repeatedly. Complete control of each element within an assembly allows efficient design.

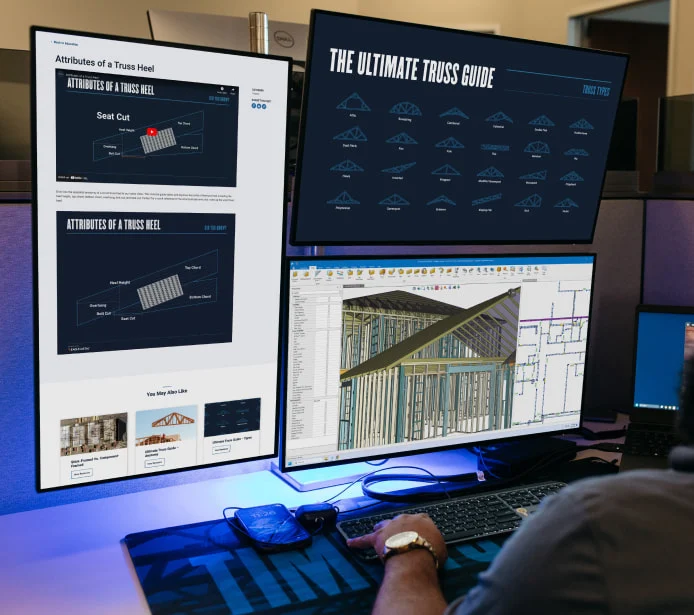

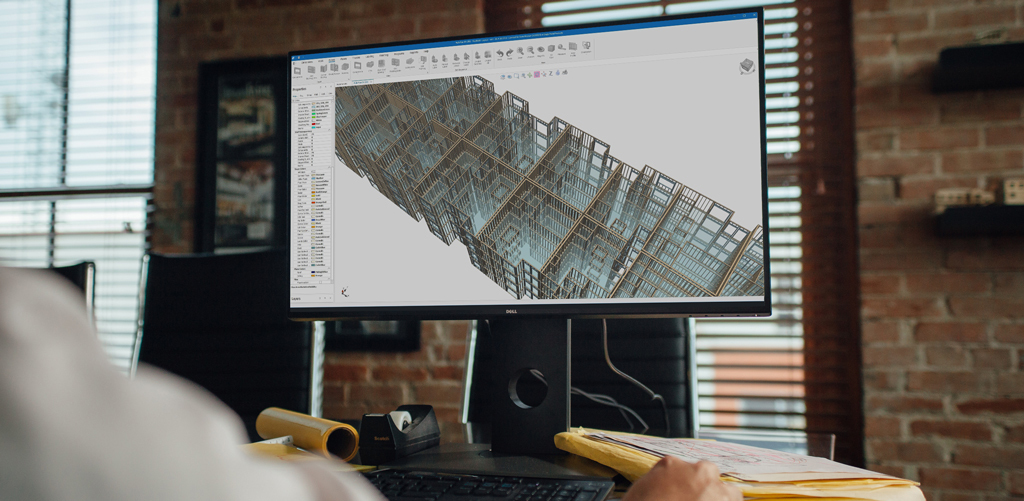

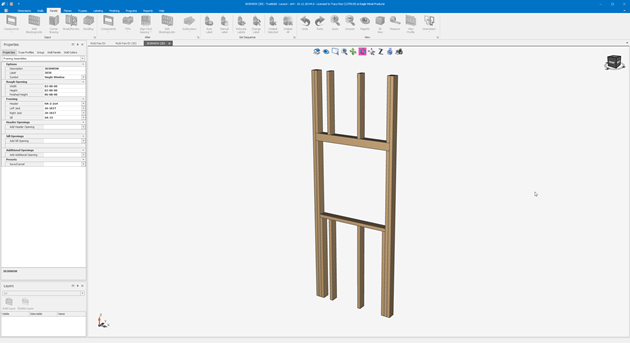

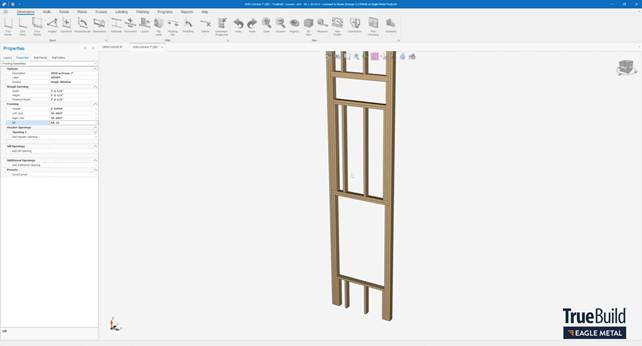

Even complex, multi-opening components can be designed, cataloged, and used again in the same model or across multiple models. Parametric 3D allows a true visual experience of exactly how these assemblies will be assembled in the plant. Even in the most complex assemblies, every member can be controlled easily and accurately.

The next article in this series will continue this exploration into parametric 3D and will discuss how to break and review, and then we’ll tackle job edits as well as bundling in subsequent installments. All of these tools help ensure that Truebuild® Layout with panel design functionality, the most advanced panel design software to hit the market in decades, will provide your panel designers with complete model control and previously unavailable features at their fingertips.

Of course, if you have any questions before, during, or after this series, please contact us via email or visit www.eaglemetal.com. Let us help empower you to build more.