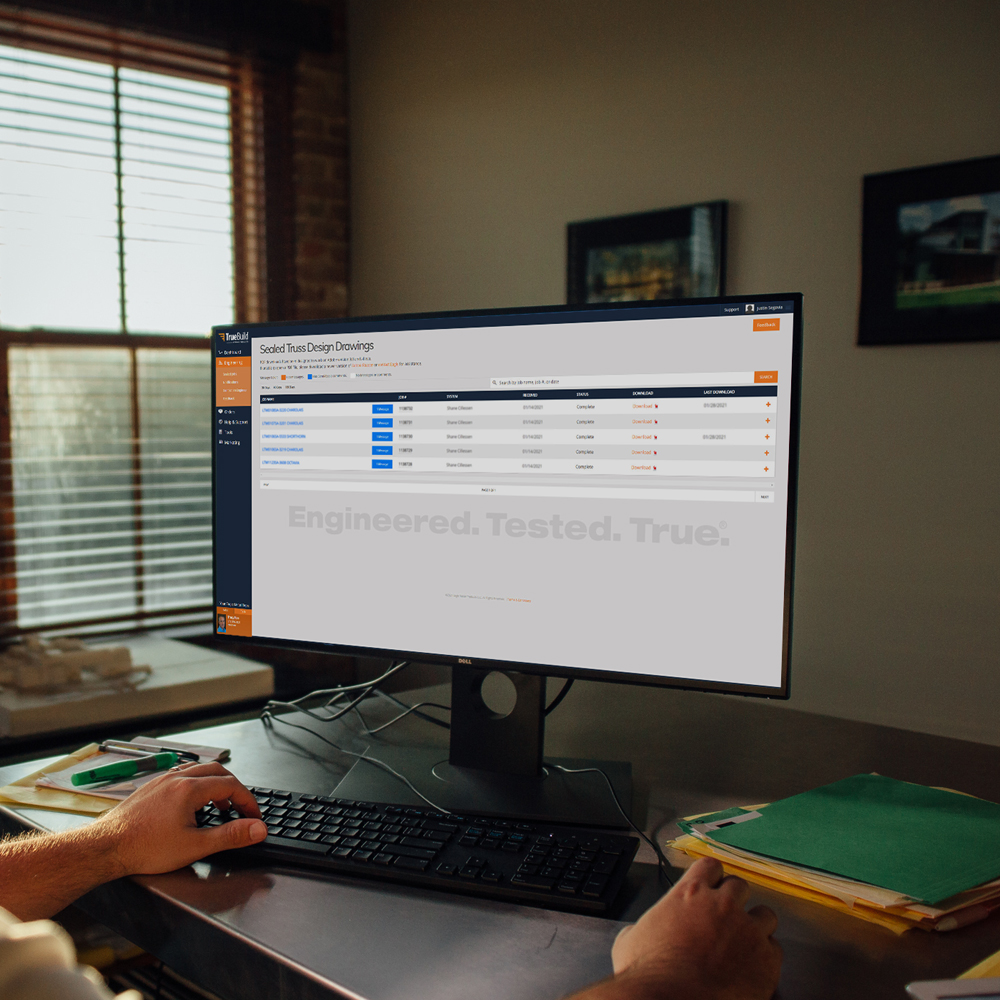

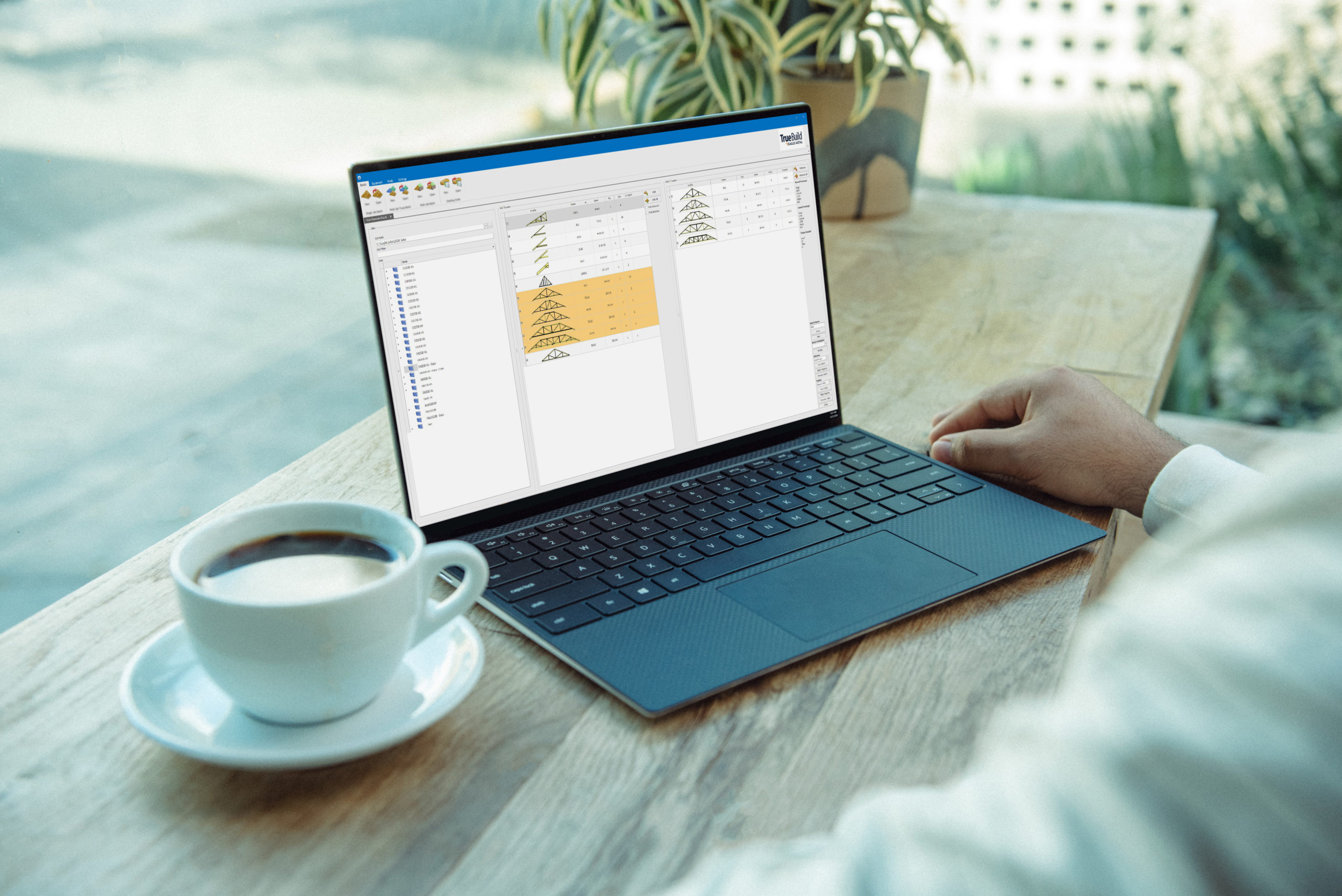

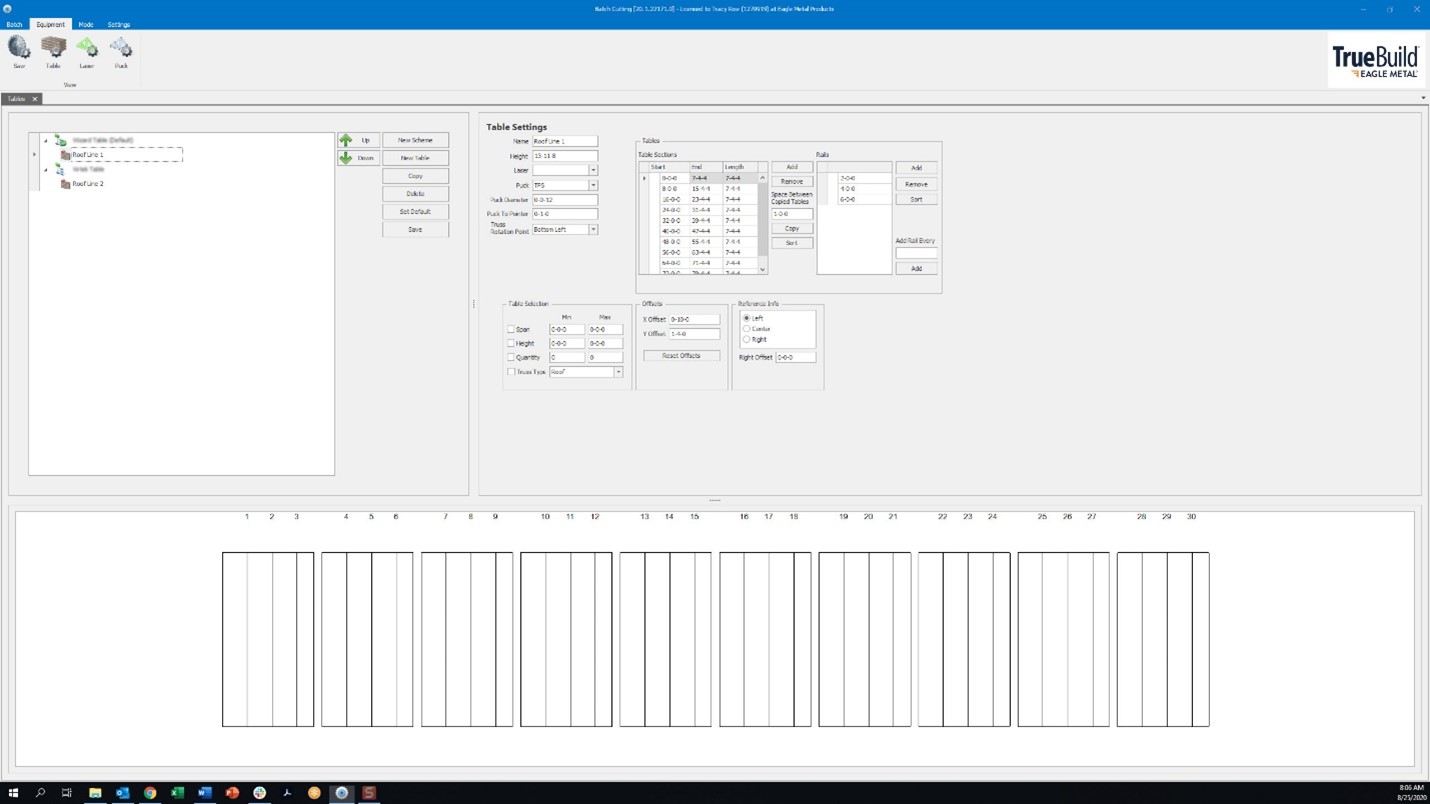

After investing in a new piece of equipment, you may need to make additional changes to a process in your operation. Typically, the desired result of an equipment purchase is increased efficiency, so your software needs to be as flexible as you are as a fabricator. TrueBuild® Batch offers an easy-to-understand interface that allows changes to be made quickly.

Our first article in this series, Maximizing Your Equipment Investment, focused on saws. This time, we will address tables.

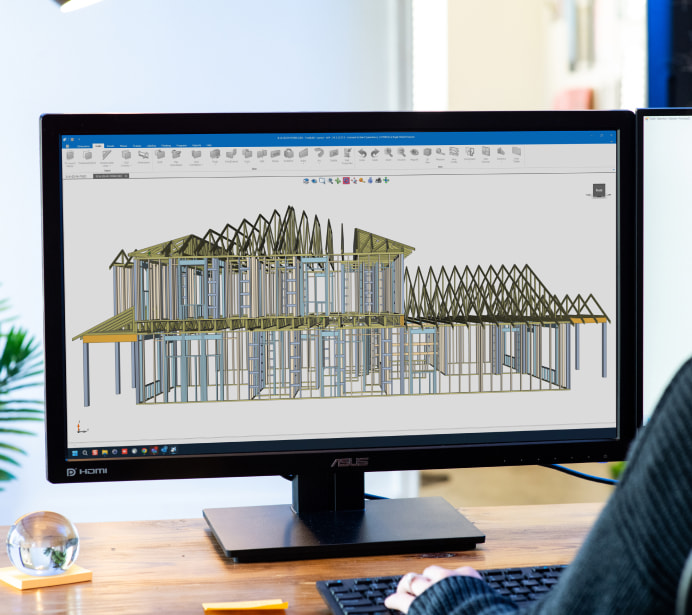

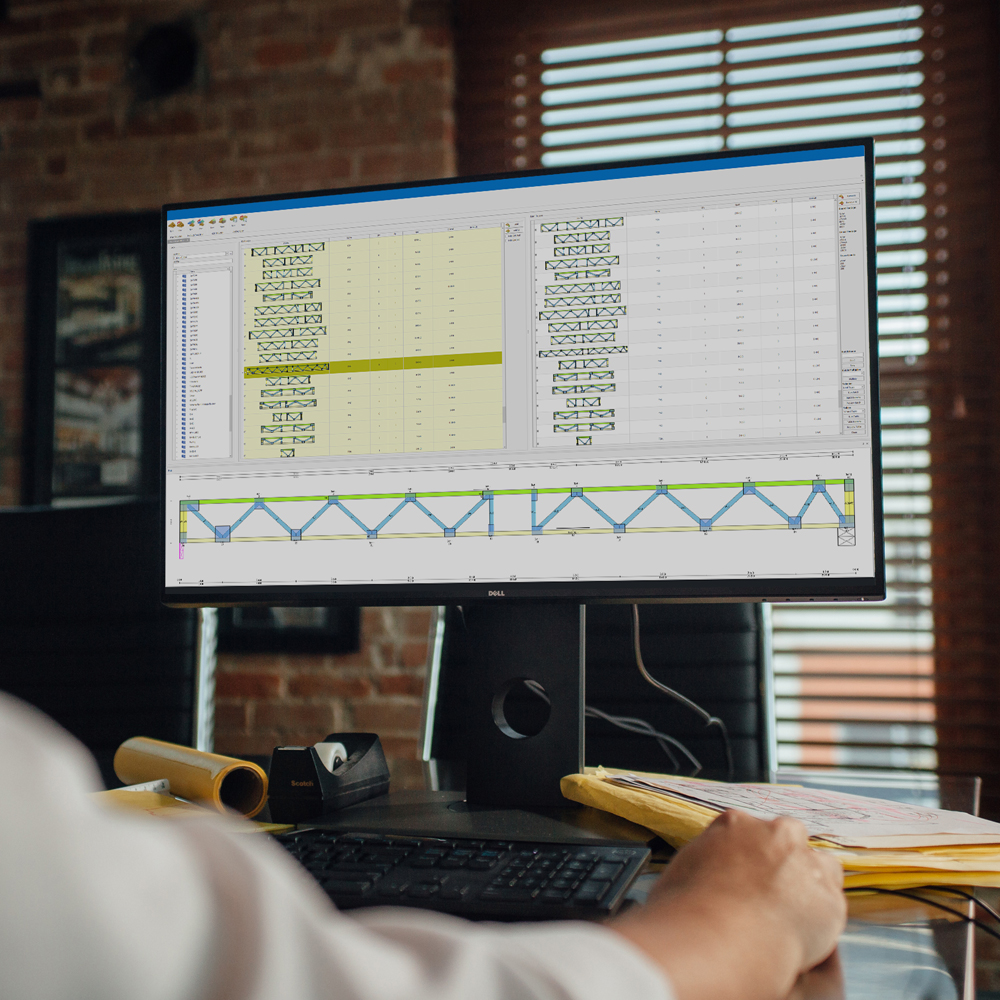

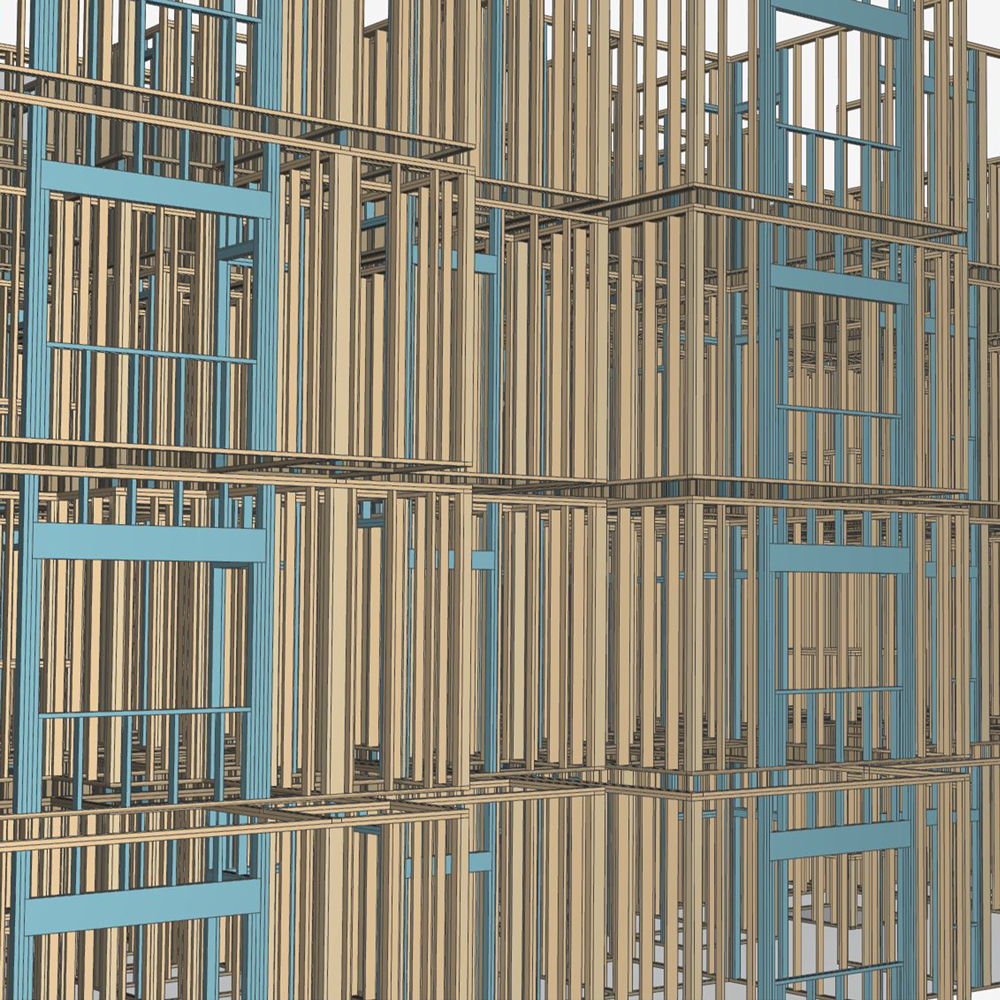

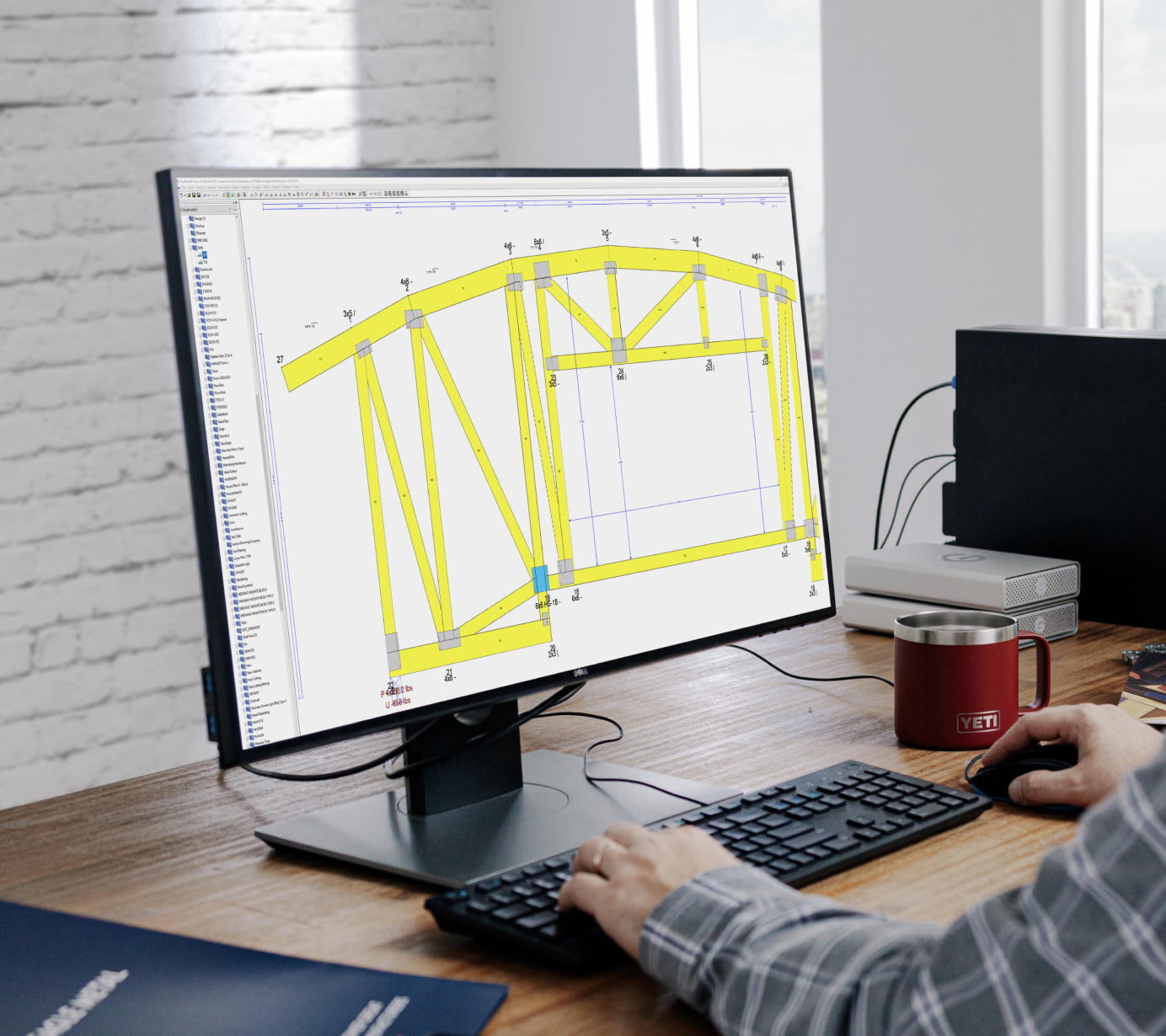

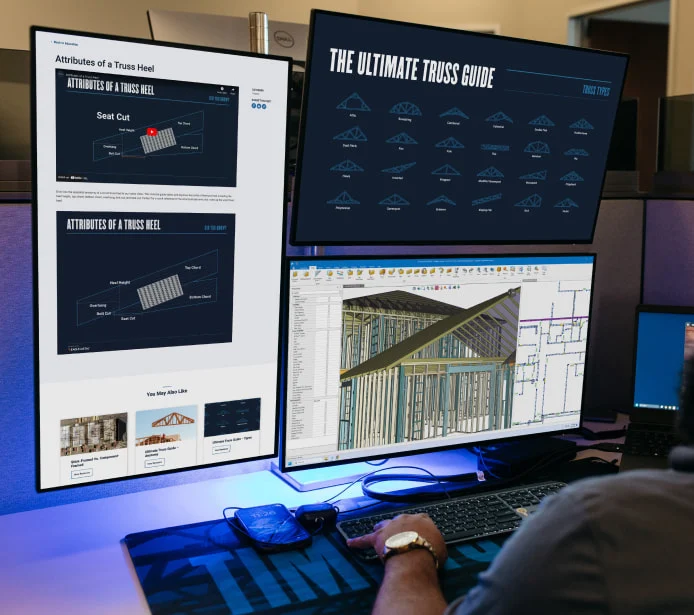

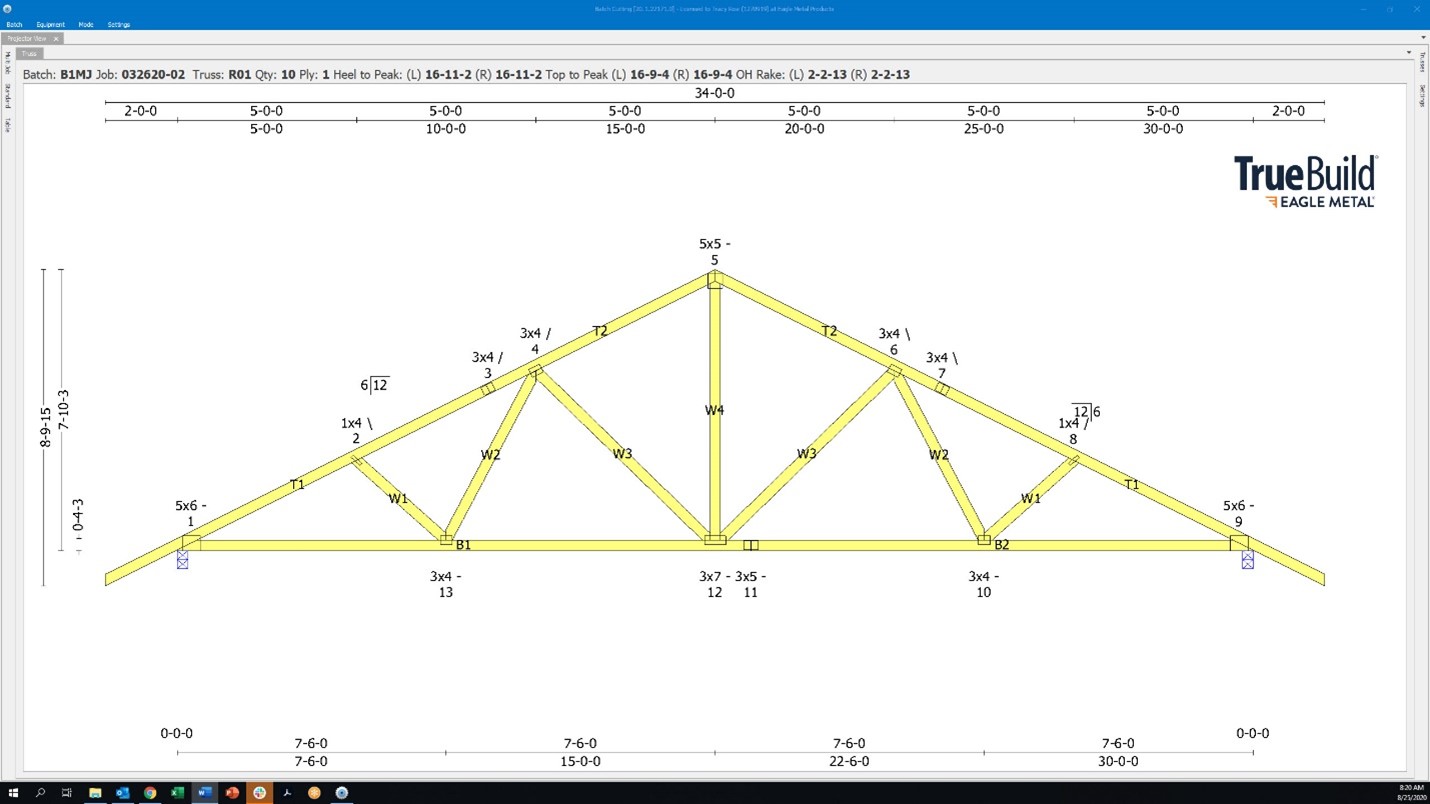

TrueBuild® Batch offers the flexibility to communicate all major automated fabrication systems on the market today. Simply replicate your table layout in the software and take total control of your output. Laser projection, automated jigging — we can drive it all. TrueBuild® Batch allows you to run your plant your way.

Is your plant paperless? Do you use hard-copy output? We have you covered either way. Predefined output paths for electronic files is a snap. Set it and forget it. Extensive reporting customization and output options make printing shop packets a simple task too. Even projecting truss output on a screen at the table is a snap.

TrueBuild® Batch is flexible enough to handle any plant process. We give you the flexibility to operate your plant your way. We give you the tools you need to build more — all with easy-to-understand graphics and crisp icons to offer ease of operation for any fabricator.

In our next installment, we are going to explore creating and managing truss batches. If you have any questions or want to learn more about this or any other piece of the TrueBuild® suite of software solutions, please contact me directly any time or visit www.eaglemetal.com.